Differences between HEPA Filter and ULPA Filter

In the realm of air filtration, HEPA (High-Efficiency Particulate Air) and ULPA (Ultra-Low Penetration Air) filters are two of the most sought-after options for achieving high levels of air purity. While both are designed to trap and remove airborne particles, there are significant differences in their performance and applications.

1. Efficiency

HEPA filters are renowned for their ability to capture particles down to 0.3 microns with an efficiency of 99.97% or higher. This makes them an excellent choice for applications requiring a high level of air filtration, such as in medical facilities and cleanrooms.

ULPA filters, on the other hand, provide an even higher level of efficiency, capturing particles down to 0.12 microns with an efficiency of 99.999% or higher. This makes them the go-to choice for applications where extremely clean air is critical, such as in pharmaceutical manufacturing and semiconductor processing.

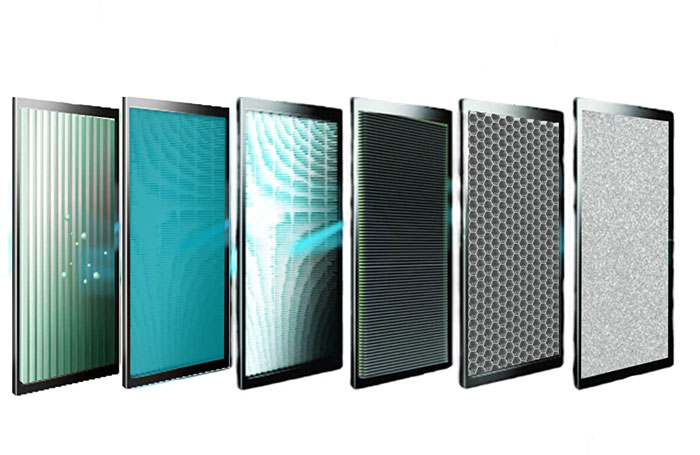

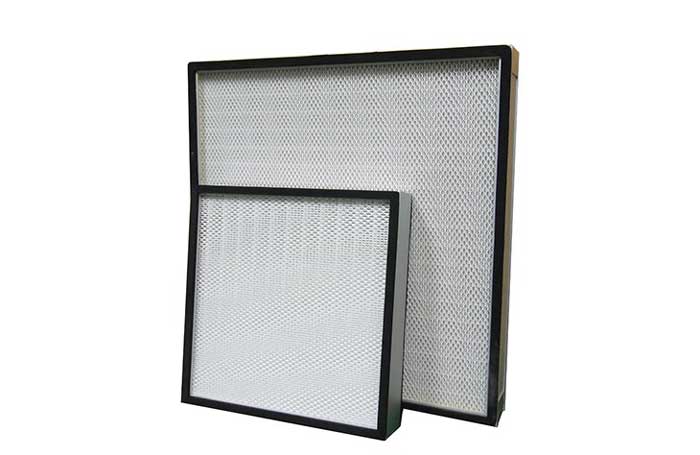

2. Material and Construction

HEPA filters are typically made of borosilicate glass fibers that are randomly arranged to form a dense web. This random arrangement allows for efficient capture of particles while maintaining good airflow.

ULPA filters, on the other hand, utilize a more complex construction, often with multiple layers of fibers arranged in a precise pattern. This allows for the capture of smaller particles with higher efficiency.

3. Airflow Resistance

Due to their dense construction, HEPA filters tend to have a higher airflow resistance compared to ULPA filters. This means that a more powerful fan or blower may be required to achieve the desired airflow rate through a HEPA filter.

ULPA filters, with their more efficient particle capture and lower airflow resistance, tend to be more energy-efficient in applications requiring high airflow rates.

4. Cost

In general, ULPA filters tend to be more expensive than HEPA filters due to their higher efficiency and more complex construction. However, the cost may be justified in applications where the highest level of air purity is critical.

5. Applications

HEPA filters are widely used in a variety of applications, including hospitals, laboratories, cleanrooms, and even some home air purifiers.

ULPA filters, on the other hand, are typically found in applications where extremely clean air is essential, such as in pharmaceutical manufacturing, semiconductor processing, and other critical industries.