High-Efficiency Air Filters in Dust Removal in Cleanrooms

Cleanrooms are specialized environments designed to maintain extremely low

levels of particulate contamination. These facilities are crucial in various

industries, including pharmaceuticals, electronics, biotechnology, and

aerospace, where the presence of dust and other contaminants can significantly

impact product quality, safety, and performance. High-efficiency air filters

play a pivotal role in dust removal within cleanrooms, ensuring a

contaminant-free workspace.

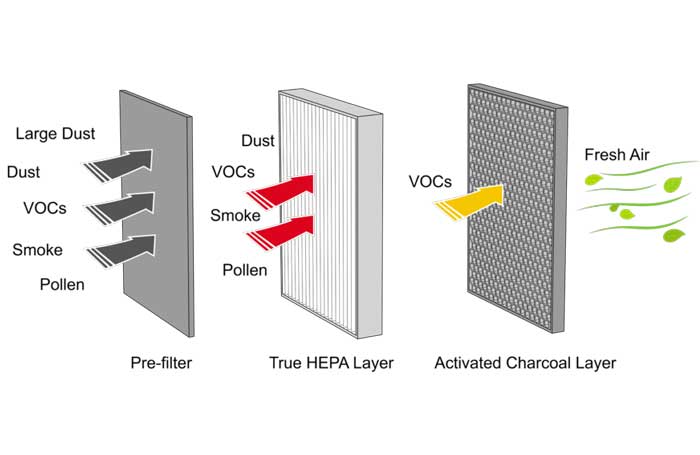

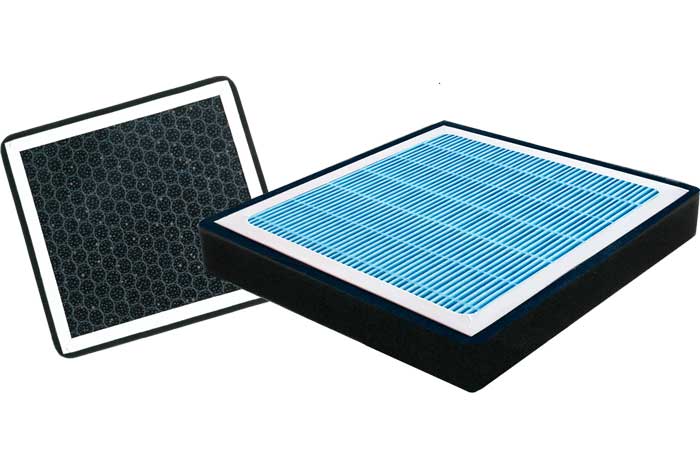

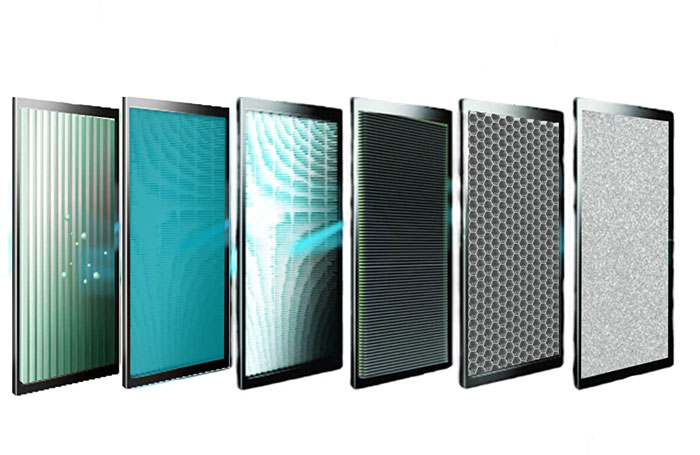

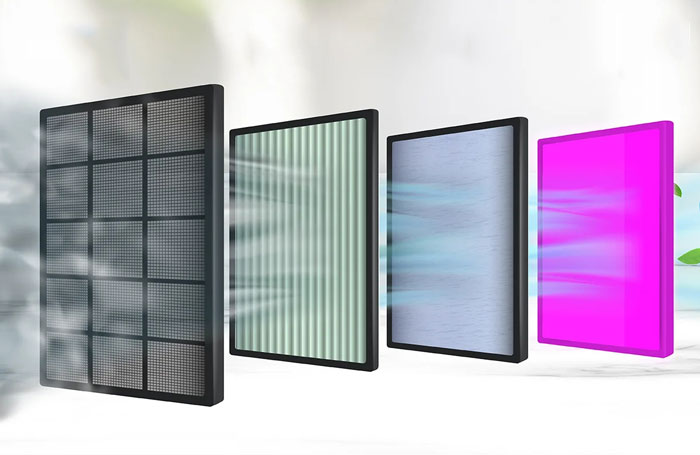

High-efficiency air filters, typically known as HEPA filters, are renowned for their ability to trap and remove minute particles from the air. These filters are constructed with a dense matrix of fibers that create a complex maze, effectively capturing particles as the air passes through. Their efficiency in removing particles down to 0.3 microns in size and larger is unmatched, making them ideal for use in cleanrooms where even the smallest particles can pose a significant threat.

In cleanrooms, high-efficiency air filters are typically integrated into the ventilation system. The incoming air is first filtered to remove any contaminants before it enters the workspace. Simultaneously, the exhaust air is also filtered to prevent the escape of any contaminants from the cleanroom. This continuous filtering process ensures that the air within the cleanroom remains free from dust, bacteria, and other harmful particles.

The application of high-efficiency air filters in cleanrooms offers several advantages. Firstly, it significantly improves the quality of the workspace, reducing the risk of contamination and enhancing the precision of manufacturing processes. This is especially crucial in industries where strict hygiene and sterility standards are mandated, such as in the production of medical devices or pharmaceuticals.

Moreover, high-efficiency air filters contribute to the overall efficiency of the cleanroom operation. By maintaining a contaminant-free environment, they help to reduce the need for frequent cleaning and maintenance, saving time and resources. Additionally, the filters' ability to trap particles effectively minimizes the risk of equipment malfunction or damage due to dust accumulation.

Furthermore, the use of high-efficiency air filters in cleanrooms is also beneficial from an environmental perspective. By efficiently removing contaminants from the air, these filters help to reduce the impact of industrial emissions on the surrounding environment. This is particularly important in areas where air quality is a concern or where strict environmental regulations are in place.

However, it is worth noting that the selection and maintenance of high-efficiency air filters are crucial for their effective performance in cleanrooms. Filters must be chosen based on the specific requirements of the cleanroom, including the particle size and concentration levels to be removed. Regular maintenance and replacement of filters are also essential to ensure their continued efficiency and prevent the buildup of contaminants.

High-efficiency air filters play a vital role in dust removal in cleanrooms. Their ability to trap and remove minute particles from the air ensures a contaminant-free workspace, improving product quality, enhancing operational efficiency, and contributing to environmental sustainability. As cleanroom technology continues to evolve, high-efficiency air filters will remain a key component in maintaining the integrity and functionality of these specialized environments.