Industrial Nonwoven Air Filter Bags

In the realm of industrial air filtration, the significance of efficient and reliable filters cannot be overstated. Among the various types of filters available, industrial nonwoven air filter bags stand out as a preferred choice for a wide range of applications. These bags, constructed from nonwoven fabrics, offer exceptional filtration performance, durability, and ease of use, making them an ideal solution for various industrial settings.

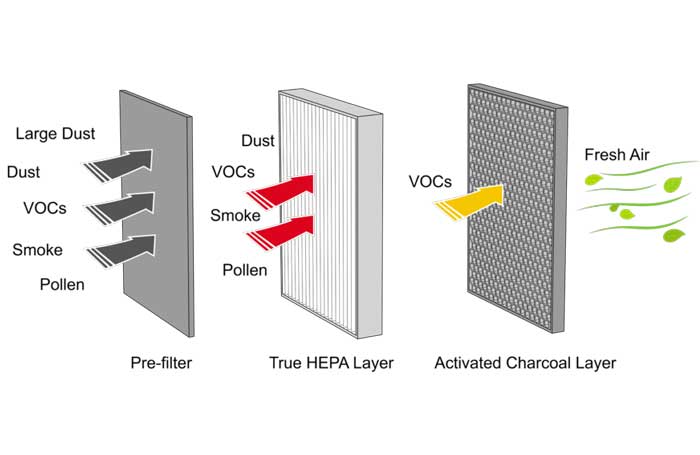

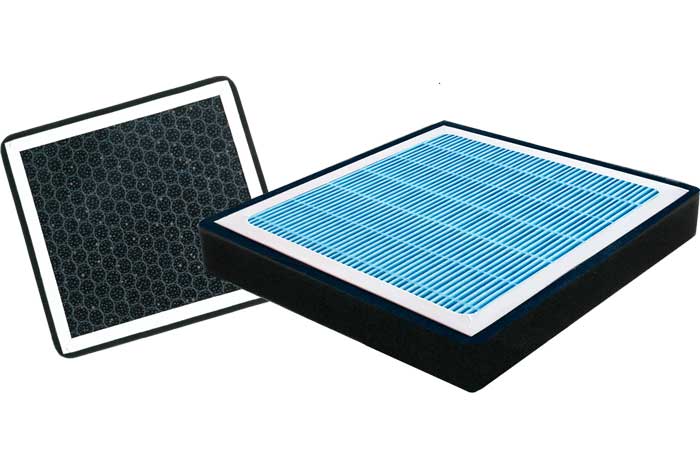

The core of an industrial nonwoven air filter bag lies in its material composition. Nonwoven fabrics are made by bonding fibers together mechanically, thermally, or chemically, without the need for traditional weaving or knitting processes. This results in a strong and porous material that can effectively trap particles while allowing air to pass through freely. The fibers used in these fabrics can be customized to target specific particle sizes, ensuring high-efficiency filtration.

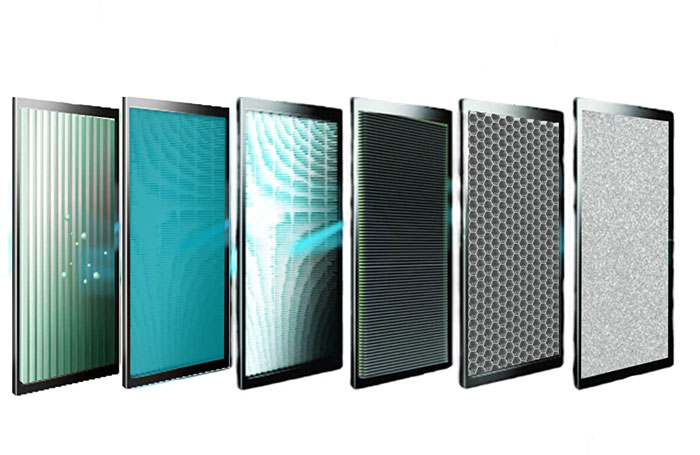

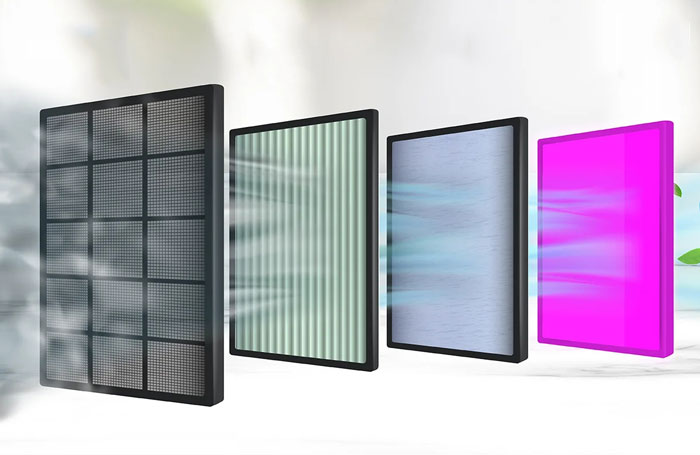

The design of industrial nonwoven air filter bags also contributes to their excellent performance. Typically, these bags feature a pleated design that maximizes the surface area available for filtration. This increased surface area allows for a higher capacity to trap particles, extending the life of the filter and reducing the need for frequent replacements. Additionally, the bags are often equipped with reinforced seams and edges to enhance durability and prevent premature wear.

The application of industrial nonwoven air filter bags is diverse and widespread. They are commonly used in dust collection systems, such as those found in manufacturing facilities, power plants, and cement production plants. The bags effectively capture dust and other airborne particles, improving air quality and protecting equipment from damage. Furthermore, they are also utilized in air conditioning and ventilation systems, where they help to remove pollutants and allergens from indoor air, creating a healthier and more comfortable environment.

One of the key advantages of industrial nonwoven air filter bags is their ease of use and maintenance. The bags are typically designed to be easily installed and removed from the filtration system, making routine maintenance and replacement a straightforward process. Additionally, the nonwoven fabric material is resistant to most chemicals and can withstand high temperatures, ensuring reliable performance even in harsh industrial environments.

Moreover, the cost-effectiveness of industrial nonwoven air filter bags is another significant advantage. While the initial investment may be comparable to other types of filters, the long-term savings from reduced maintenance costs and extended filter life make them a cost-effective solution. Additionally, the availability of various sizes and configurations allows for customization to specific application needs, further enhancing their cost-effectiveness.

Industrial nonwoven air filter bags are a highly efficient and reliable solution for air filtration in various industrial settings. Their excellent filtration performance, durability, ease of use, and cost-effectiveness make them a preferred choice for dust collection systems, air conditioning, and ventilation systems. As industrial air quality standards continue to rise, industrial nonwoven air filter bags will play an increasingly important role in ensuring clean and healthy indoor environments.