Introducing the High-Efficiency Air Filter for Cleanroom Applications

In today's manufacturing environment, maintaining a dust-free and

contaminant-free workspace is paramount. This is especially true in industries

such as pharmaceuticals, electronics, and biotechnology, where the slightest

particle contamination can lead to product defects, equipment malfunctions, or

even health hazards. To address these challenges, the high-efficiency air filter

for cleanrooms has emerged as a crucial tool in ensuring a pristine work

environment.

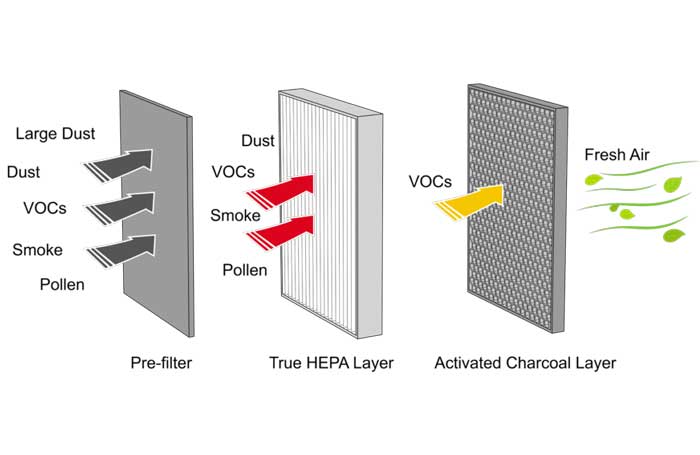

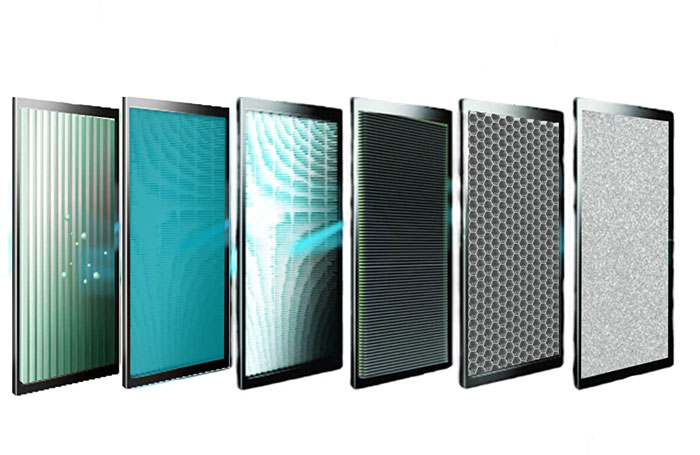

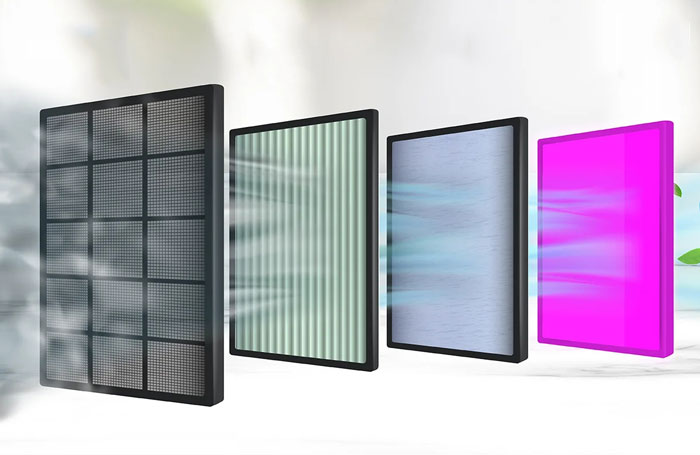

The high-efficiency air filter for cleanrooms is a specialized type of air purification system designed to remove airborne particles, including dust, bacteria, viruses, and other contaminants. These filters are typically installed in the air handling units of cleanrooms, capturing and trapping particles as the air passes through them.

One of the key features of these filters is their high-efficiency rating. They are capable of capturing particles down to submicron sizes, ensuring that even the smallest contaminants are removed from the air. This level of filtration is achieved through the use of advanced materials and precise manufacturing techniques, which create a dense filter media that traps particles effectively.

The design of these filters also takes into account airflow and pressure drop. They are optimized to provide maximum filtration efficiency while minimizing resistance to airflow, ensuring that the cleanroom maintains a constant and comfortable air supply. This is crucial in maintaining the integrity of the cleanroom environment and preventing any disruptions to the manufacturing process.

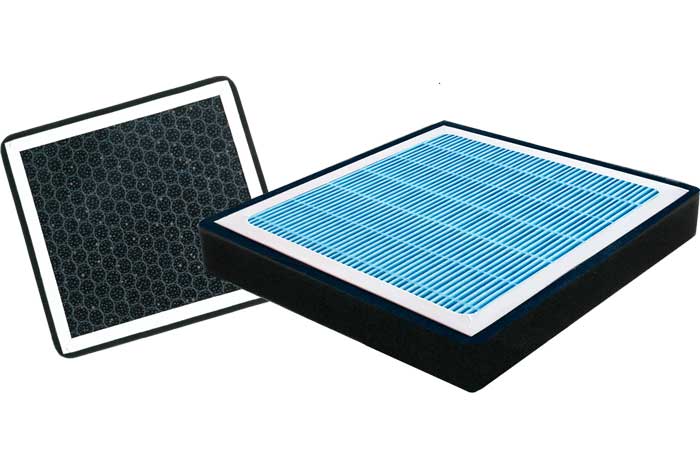

In addition to their filtration capabilities, the high-efficiency air filters for cleanrooms are also designed for durability and reliability. They are constructed from durable materials that can withstand the rigors of continuous use in a cleanroom environment. The filters also undergo rigorous testing to ensure that they meet or exceed industry standards for performance and longevity.

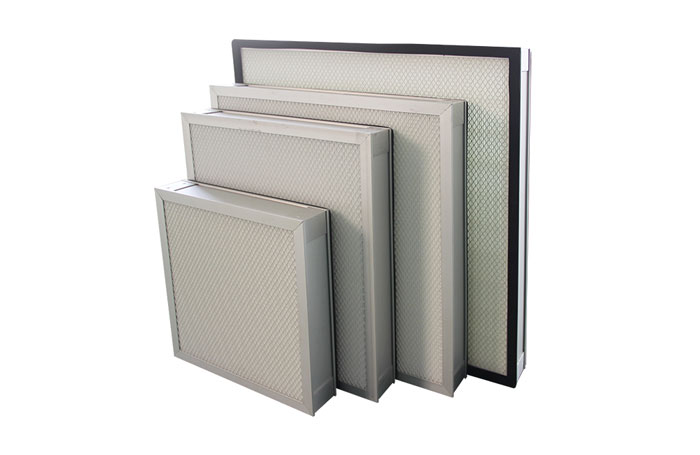

Moreover, these filters are easy to install and maintain. They are designed to fit into standard air handling units, and replacement filters are available in a variety of sizes and configurations to suit different cleanroom setups. Regular maintenance, such as filter replacement, is straightforward and can be performed by trained personnel with minimal downtime.

The use of high-efficiency air filters in cleanrooms not only improves air quality but also contributes to the overall efficiency and safety of the manufacturing process. By reducing particle contamination, these filters help to minimize product defects and improve the overall quality of the final product. Additionally, they protect sensitive equipment from dust and debris, reducing the risk of malfunction and extending the lifespan of the equipment.

The high-efficiency air filter for cleanrooms is a crucial component in maintaining a dust-free and contaminant-free workspace. Its ability to capture even the smallest particles, combined with its durability and ease of maintenance, makes it an essential tool in ensuring the integrity and efficiency of the manufacturing process. As the demand for cleaner and safer manufacturing environments continues to grow, the high-efficiency air filter for cleanrooms will play an increasingly important role in meeting these challenges.