Specialized Air Filters for Pharmaceutical Factories

In the highly regulated and precision-oriented environment of pharmaceutical

factories, specialized air filters play a crucial role in ensuring the quality

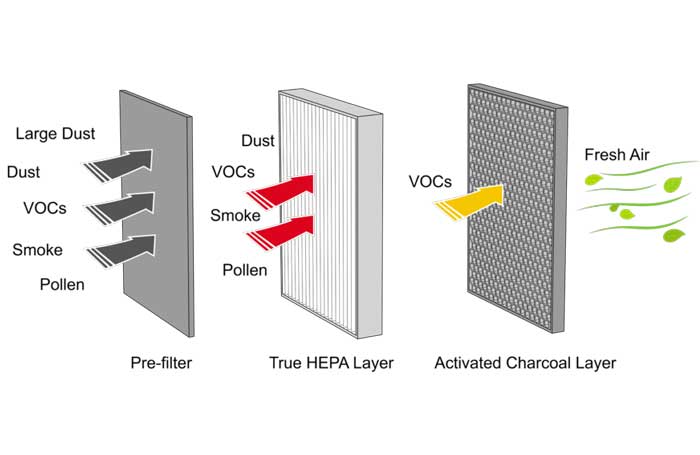

and safety of medications. These filters are designed to remove airborne

contaminants, particles, and microorganisms, thereby safeguarding the purity of

the manufacturing process.

Pharmaceutical factories require a strict control over the indoor air quality to prevent any contamination that could compromise the integrity of their products. Specialized air filters are tailored to meet the unique challenges of this environment, offering a high level of filtration efficiency and reliability.

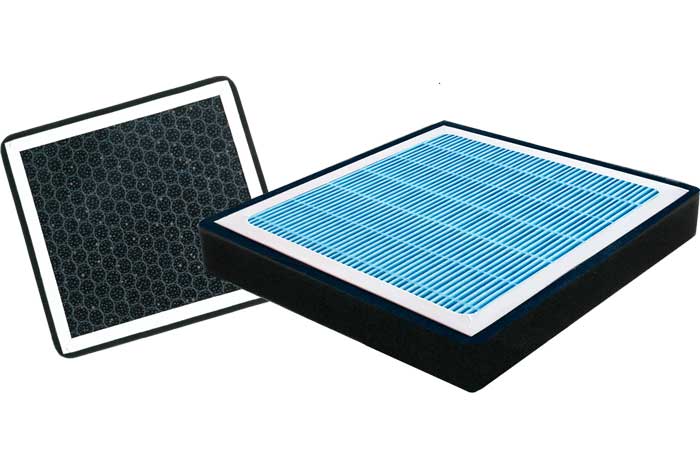

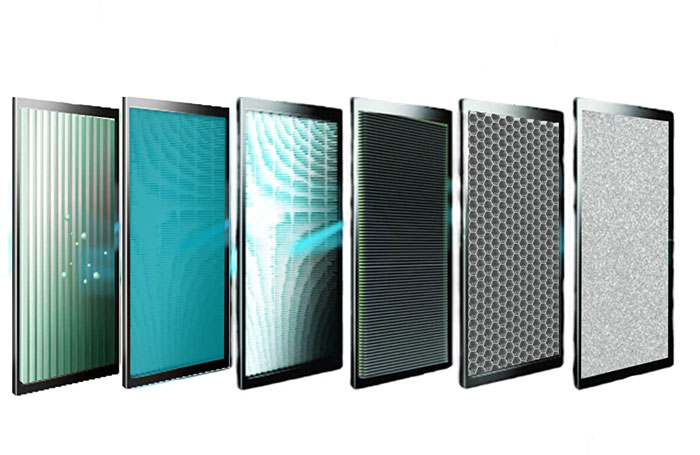

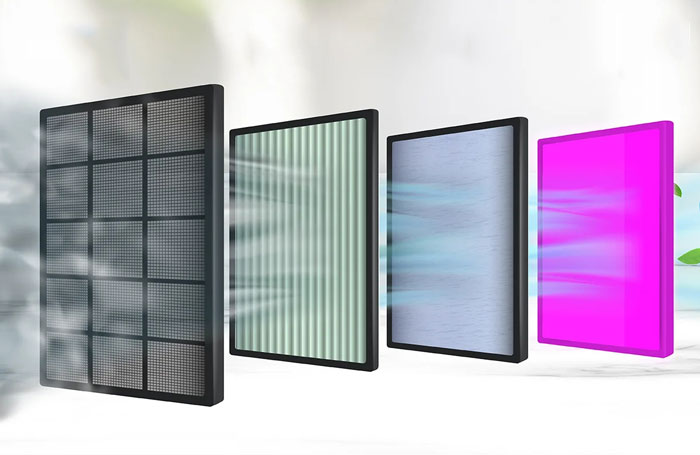

The design of these filters often incorporates high-grade filter media, which can effectively trap particles down to submicron levels. This ensures that even the smallest contaminants, such as dust, bacteria, and viruses, are removed from the airflow, preventing them from entering the manufacturing area.

Moreover, the filters are often equipped with additional features that enhance their performance. These may include antimicrobial coatings that prevent the growth of bacteria or fungi on the filter surface, as well as special sealing mechanisms that prevent air leakage around the filter housing.

The selection of the appropriate air filter for a pharmaceutical factory depends on various factors, including the type of manufacturing process, the required level of air purity, and the specific contaminants that need to be removed. Different filters are available with different efficiency ratings, particle retention capabilities, and flow rates, allowing for a tailored solution for each application.

The installation and maintenance of these specialized air filters are also crucial for their effective operation. Proper installation ensures that the filters fit securely within the air handling system, while regular maintenance ensures that they remain in good condition and continue to perform at their optimal level.

In addition to their role in maintaining air purity, specialized air filters for pharmaceutical factories also contribute to energy efficiency. By reducing the pressure drop across the filter media, these filters help minimize the energy required to operate the air handling system, leading to cost savings and a reduced environmental impact.

Specialized air filters are a vital component of the pharmaceutical manufacturing process. They play a crucial role in ensuring the quality, safety, and efficiency of the medications produced, while also contributing to a healthier and more sustainable manufacturing environment.