The Application of High-Efficiency Filters in Workshops

In today's industrial environment, maintaining a clean and contaminant-free

workspace is crucial for ensuring the quality of production and the safety of

employees. High-efficiency filters, also known as HEPA (High-Efficiency

Particulate Air) filters, play a pivotal role in achieving this goal, especially

in workshops and manufacturing facilities.

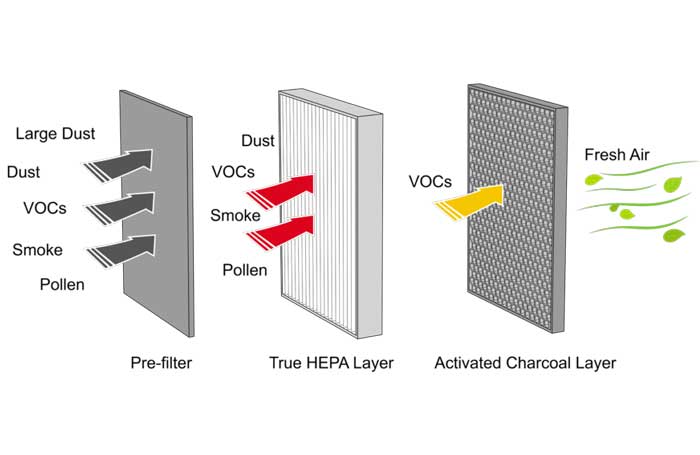

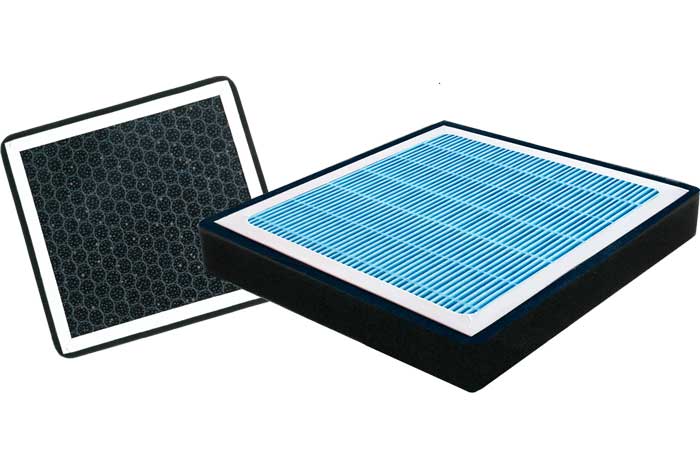

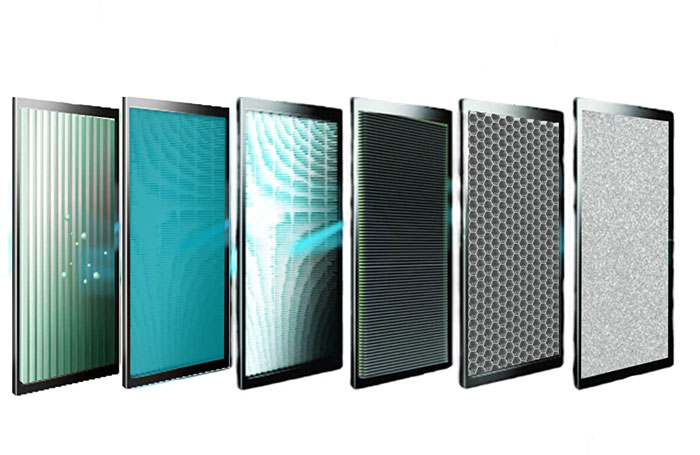

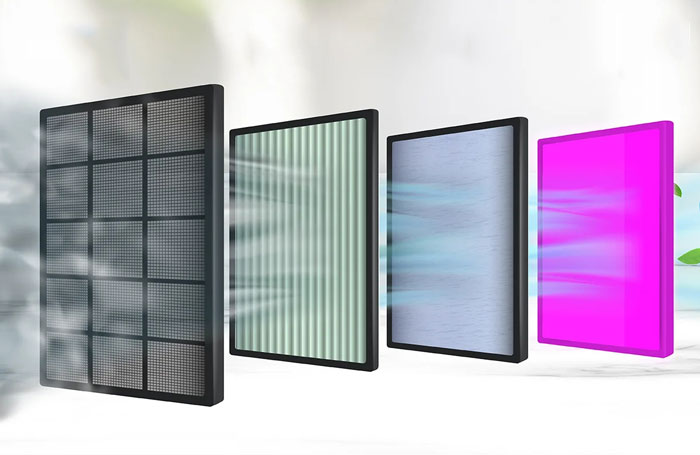

HEPA filters are designed to capture and retain particles of 0.3 microns or larger with a minimum efficiency of 99.97%. This makes them ideal for use in workshops where the presence of dust, dirt, and other airborne contaminants can significantly impact the performance and durability of machinery and equipment.

In workshops, high-efficiency filters are typically integrated into ventilation systems. These systems draw in air from the outside and pass it through the filters, removing harmful particles before distributing the clean air throughout the workspace. This ensures that the air within the workshop remains contaminant-free, providing a safer and more conducive environment for employees to work in.

The application of high-efficiency filters in workshops brings several benefits. Firstly, it improves the overall air quality within the workspace, reducing the risk of respiratory illnesses and other health issues caused by exposure to harmful particles. Secondly, it protects machinery and equipment from dust and dirt accumulation, extending their lifespan and reducing the need for frequent maintenance.

Moreover, the use of high-efficiency filters in workshops can also improve the quality of the final products. In industries where cleanliness is critical, such as electronics and pharmaceuticals, even the smallest particles can contaminate and damage products. By filtering out these particles, workshops can ensure that their products meet the highest standards of quality and safety.