Types of HEPA filters

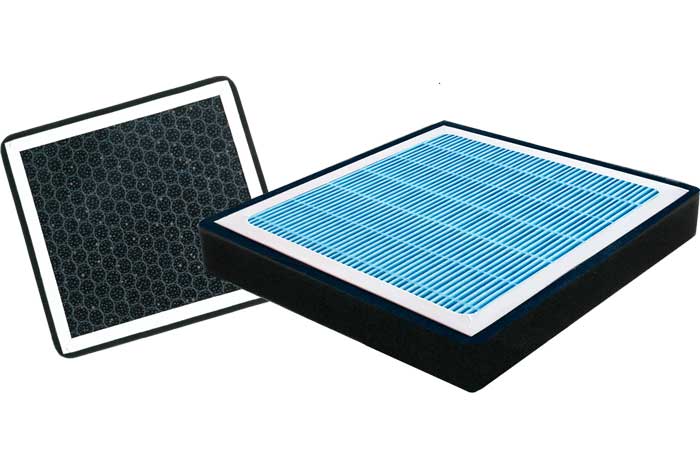

HEPA filters differ by material: washable (reusable) and non-washable (replaceable or disposable).

Washable HEPA filters are made of fiber fluoroplastic (expanded Poly Tetra Fluor Ethylene (ePTFE fibers)). It is a synthetic hydrophobic material. As a rule, manufacturers add porous activated carbon to the filtration material. It neutralizes odors, traps microscopic particles of dust and gasses from the air. Mainly, high class efficiency filters are made of this material.

Advantages of washable HEPA filters:

Filtration material does not deform when wet (can be cleaned by water).

Holding of dust particles sized 0.04-0.06 micron.

Lasts longer than replaceable filter.

Disadvantages of washable HEPA filters:

Expensive

Residual moisture on the filter may cause mold, fungus and unpleasant odor, thus filter must be well dried after washing.

Replaceable (disposable) HEPA filters are made of layers of thin paper and fiberglass. Also some manufactures can use a lightweight cardboard as a filtration material. Therefore, it is prohibited to wash such filter, because it deforms immediately. It is also ineffective to clean it by blowing air because dust microparticles are retained in the filter fibers and cannot be cleaned. It is better to replace it with a new one.

Pros of non-washable HEPA filters:

Do not obstruct airflow.

Relatively cheap.

Cons of non-washable HEPA filters:

Low wear resistance of filtration material. It is easy to damage the filter.

Filtration material is deformed when wet.

Skipping dust particles sized less than 0.3 micron.

To prevent reproduction of harmful microorganisms, some manufacturers can soak filtration material in special chemical composition. So, when buying a HEPA filter, we recommend asking about this.